Curiosità infinita

Ci vuole una curiosità infinita per essere un ingegnere Naim Audio. Definire, testare e ridefinire ogni componente e materiale in ogni prodotto che progettiamo, ignorando le tendenze, per trovare modi nuovi e migliori per ottenere prestazioni all'avanguardia.

FILTRO DIGITALE A 40 BIT IN VIRGOLA MOBILE

Il filtro digitale dell'NDS è matematicamente abbastanza preciso da contare232 x2256 secondi (cioè un 5 seguito da 86 zeri). In altre parole, è abbastanza potente da contare ogni secondo dall'inizio dell'universo molte volte con una precisione millimetrica. Questo livello di precisione è essenziale per mantenere il rumore aritmetico del filtro sempre al di sotto di - 144 dB (il rapporto segnale/rumore teorico dell'audio PCM a 24 bit) per ottenere la migliore qualità sonora possibile.

Potere assoluto

La nostra determinazione a seguire la nostra strada è più evidente che nella comprensione degli alimentatori di alta qualità. Il miglioramento dell'alimentazione ha un impatto chiaro e tangibile sulla qualità del suono, come abbiamo potuto constatare più volte. Ecco perché i prodotti Naim sono dotati di grandi trasformatori con avvolgimenti isolati. La nostra filosofia è esemplificata nella nostra gamma di alimentatori separati che forniscono un'alimentazione fluida, stabile e a basso rumore per far brillare le elettroniche audio.

Disaccoppiamento e isolamento

Ridurre al minimo le interferenze meccaniche, elettromagnetiche e termiche tra i componenti è fondamentale per la progettazione di Naim Audio.

Il disaccoppiamento delle prese per eliminare le interferenze dalla rete elettrica in entrata e la sospensione delle schede dei circuiti su sottopiastre di ottone per creare un ambiente isolato per i componenti elettronici critici sono due applicazioni di questo principio.

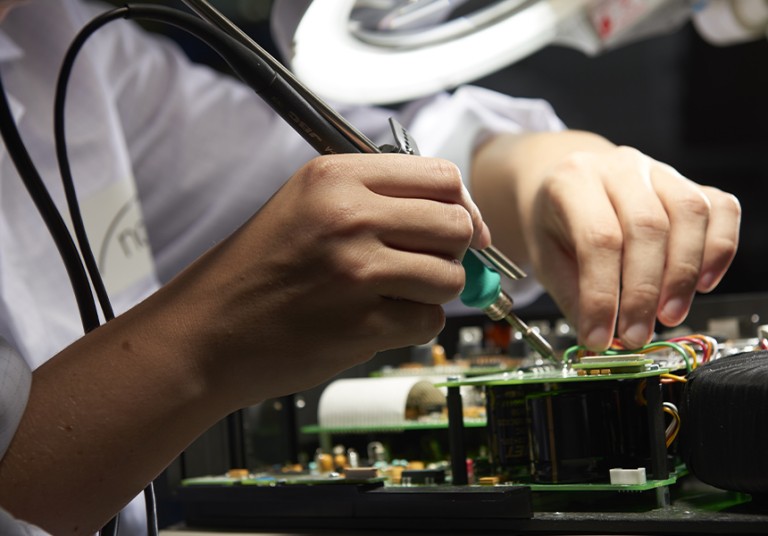

Un esempio meno ovvio è la creazione manuale di leggere curve nei singoli resistori, per ridurre l'interferenza microfonica (vibrazioni microscopiche che degradano la qualità del suono). Tuttavia, tecniche simili vengono applicate a ogni livello della progettazione e della costruzione. E introduciamo tecniche solo se si dimostrano efficaci e ripetibili nei test di ascolto.

Componentistica abbinata a mano

La corrispondenza delle caratteristiche dei componenti critici per il suono per ciascun canale (altoparlante destro e sinistro) di un amplificatore può migliorare significativamente la qualità del suono. I lotti di resistenze vengono in genere abbinati con un margine di errore del 5%. Attraverso i test di ascolto, abbiamo scoperto che se la resistenza dei canali destro e sinistro viene accoppiata con un margine inferiore allo 0,5%, la musica diventa molto più comunicativa e coinvolgente. In seguito a questa scoperta, è stato concepito un processo di produzione su misura che ci consente di abbinare le resistenze a mano.

La via dell'audio di Naim

Dalla nostra creazione nel 1973, siamo riusciti a stare al passo con le tendenze e a fare affidamento soprattutto sulla nostra idea di ciò che rende il miglior sistema musicale in una sala d'ascolto.

STORIA DI NAIM AUDIO

La nostra storia inizia con la passione di un uomo per la musica e si snoda attraverso cinque decenni e una serie di lanci di prodotti iconici fino ai giorni nostri.

SU NAIM AUDIO

Ogni prodotto Naim è concepito, progettato e ingegnerizzato interamente al servizio del suono, rivelando un'esperienza pura della musica che è il più vicino possibile alla sua fonte originale.

Unisciti alla comunità

Ricevi un'anteprima delle ultime innovazioni audio di Focal e Naim iscrivendoti alle nostre esclusive newsletter. Siate tra i primi a scoprire i nostri nuovi prodotti e a ricevere informazioni privilegiate direttamente nella vostra casella di posta elettronica.

Newsletter

Nuovi prodotti ed edizioni limitate

Inviti a eventi esclusivi

Beneficiare di offerte speciali